Black Fused Alumina Oxide Abrasives Wheel Coated Abrasives Raw Material

Basic Info

| Model NO. | Black fused alumina-10 |

| Natural Abrasive Type | Natural Corundum |

| Artificial Abrasive Type | Corundum Abrasives |

| Application | Metal Parts |

| Function | Surface Deburring |

| Source | Artificial Abrasives |

| Particle Size | Abrasive |

| Hardness | Conventional Abrasive |

| Al2O3 | 85% |

| Ti2o | 2 |

| Fe2o3 | 6 |

| Sio2 | 6 |

| Melting Point | 2050 Degree Celsius |

| Maximum Operation Temperature | 1850 Degree Celsius |

| Bulk Density | 1.65t/M3 |

| Linear Expansivity | 7-9 |

| Color | Black |

| Packing | Ton/Bag or 25kg/Bag as Customers′s Request |

| Transport Package | According to Customer′s Request |

| Specification | According to customer′s request |

| Trademark | GYFT |

| Origin | China |

| HS Code | 2818109000 |

| Production Capacity | 3600tons |

Product Description

Black Fused Alumina Chemcal Analysis

Black aluminum oxide fused corundum is also known as low aluminumcorundum. It is also a new type product of polishing material, and it isa dark gray crystal body made α-Al2O3 and ferropicotite as main ore inthe electric arc furnace by smelting the bauxite. It has characteristics ofmoderate hardness, high toughness, high temperature resistance, andstable thermal stability. It is mainly suitable for free grinding, such ascoarse grinding before electroplating products, mainly for polishing andsandblasting of stainless steel, fabricated metal products.

Product Parameters

Chemical Composition (% by weight)

Black Fused Alumina physical properties

Hardness (Mohs) ≥ 9.0

Melting point (°C) 2050

The maximum temperature (°C) 1850

True Density (g/cm3) ≥ 3. 50

Linear expansion coefficient (0-1600 °C) 7-9

High content industry calcined black fused alumina Application

| Grade | Chemical Composition | |||

Al2O3 | SiO2 | Fe2O3 | TiO2 | |

| I | 85 | 11 | 5.0 | 1.5-3.5 |

| II | 75-81 | 9-12 | 4-6 | 2-3 |

| III | 65 | 10 | 7.0 | 1.5-3.0 |

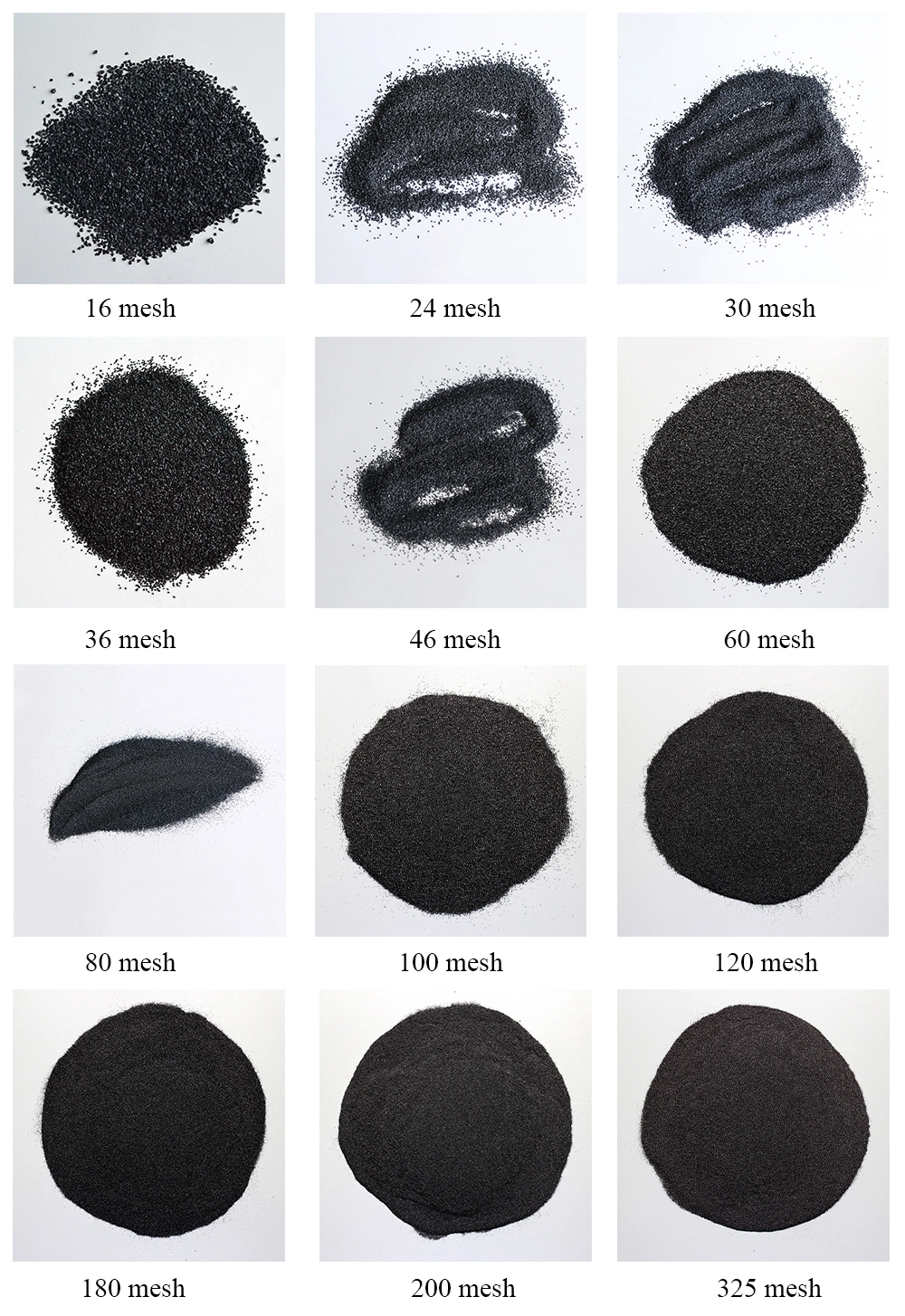

| Grit | F 8 10 12 16 24 36 46 60 80 100 120 150 180 220 325 MESH | Fine powder: 400 600 800 1000 1500 2000 MESH etc. | ||

Application

1. Extremely hard, sharp, and durable abrasive2. Angular shape and fairly high bulk density will produce a matte surface finish3. Abrasive is generally reusable many times because of its hardness and durability4. Anchor pattern creation prior to coating or bonding5.Rust, scale, or other tough contaminant removal6. Application must tolerate some metal removal7. Used for grinding and lapping as well as abrasive blasting

Gongyi Fengtai is a manufacturer integrating production and sales. We have abundant strength and enthusiastic service attitude. We have exported to many countries, such as Europe, Asia, Africa, Australia, South America and so on, and have been well received by customers.

In addition, we have professional R&D and sales teams, and own factories and laboratories. Each batch of our product samples will be inspected by our quality inspector. After a series of tests, our products will be delivered to customers to provide them with quality assurance.FAQ

FAQ:

Q: Are you trading company or manufacturer ?

A: We are factory.So you do not have to worry about quality and price, we can guarantee the best quality and the most reasonable price

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us as below: