China Silicon Nitride Ceramic Product Manufacturer

Basic Info

| Model NO. | NA |

| Application | Industrial Ceramic |

| Material | Silicon Nitride |

| Type | Ceramic Parts |

| Size | According to Drawings |

| Tolerance | +/-0.01mm |

| Color | Black |

| Density | 3.2g/cm3 |

| Lead Time | 20-30days |

| Transport Package | Box/Carton/Wooden Case |

| Specification | Customized |

| Trademark | Hard |

| Origin | China |

| HS Code | 8547100000 |

| Production Capacity | 1000PCS/Month |

Product Description

Product Destription

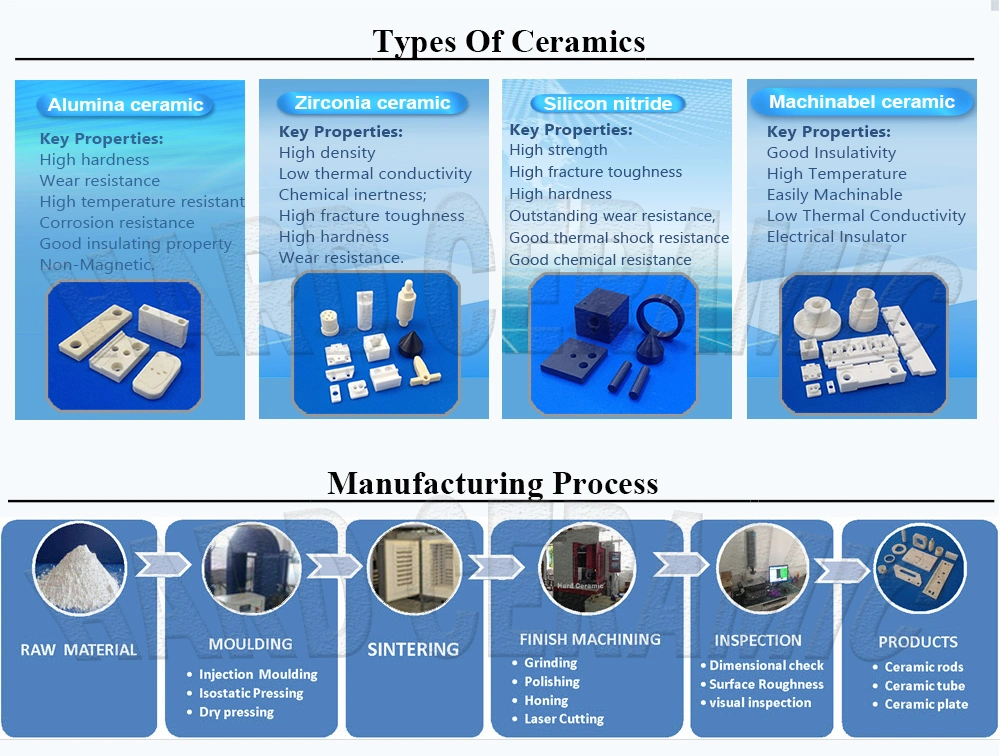

Customized high hardness Si3N4 silicon nitride ceramic industrial parts

Silicon nitride ceramic is an inorganic material ceramic that does not shrink when sintered. Silicon nitride is very strong, especially hot pressed silicon nitride, which is one of the hardest substances in the world. It has high strength, low density and high temperature resistance. Si3N4 ceramic is a covalent bond compound. The basic structural unit is a [SiN4] tetrahedron. The silicon atom is located at the center of the tetrahedron. There are four nitrogen atoms around it, which are located at the four vertices of the tetrahedron, and then every three A tetrahedron shares the form of an atom, forming a continuous and robust network structure in three dimensions.

High strength over a wide temperature rangeHigh fracture toughnessHigh hardnessOutstanding wear resistanceGood thermal shock resistanceGood chemical resistance

Company Information

Factory Show

Our Products

Ceramic Properties

| Properties | Units | 96% Al2O3 | 99% Al2O3 | Zirconia | Silicon Nitride | Machinable Ceramic |

| Material Characteristics | ||||||

| Gas Permeability | 0 | 0 | 0 | 0 | 0 | |

| Water Absorption | % | 0% | 0% | 0% | 0% | 0.038% |

| Colour | White | Ivory | White | Grey | White | |

| Density | g/cm3 | 3.7 | 3.85 | 6 | 3.2 | 2.7 |

| Physical Characteristics | ||||||

| Hardness | Kg/mm2 | 1100 | 1400 | 1100 | 1600 | 1175 |

| Modulus of Elasticity | Gpa | 300 | 350 | 200 | 300 | 65 |

| Flexural Strength | Mpa | 300 | 340 | 1150 | 600 | 108 |

| Compressive Strength | Mpa | 2100 | 2200 | 2500 | 2500 | 488 |

| Fracture Toughness | Mpam1/2 | 3.5 | 4 | 12 | 6 | |

| Thermodynamic Property | ||||||

| Max Use Temperature | °C | 1500 | 1650 | 1500 | 1800 | 800 |

| Thermal Conductiviey | W/(m.k) | 25 | 27.5 | 2.5 | 20 | 1.68 |

| Thermal Expansion Coefficient | 10-6/°C | 7.5 | 8 | 10 | 3.2 | 8.6 |

| Thermal Shock Resistance | △T°C | 200 | 200 | 250 | 600 | 200 |

| Specific Heat | J/kg.K | 860 | 860 | 500 | 500 | |

| Electrical Specification | ||||||

| Dielectric Strength | KV/mm | 12 | 10 | 5 | 40 | |

| Dielectric Constant | εr | 9.5 | 9.1 | 12 | 6 | 7 |

| Volume Resistivity | Ω | ≥1014 | ≥1014 | ≥1010 | ≥1014 | ≥1016 |

| Dielectric Loss Angle | 0.0002 | 0.0002 | 0.001 | |||

Packing & Delivery

Why Choose Us?

1.12 years of professional production industrial ceramics factory2. High quality products with low price3. High precision parts with lowest tolerance4. Show time for production5. Has a group of experienced, professional and efficient R&D team6. Has a good reputation in China and abroad. 7. MOQ is not limited, small quantity is welcome. 8. Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance, balance before shippment.

Contact Us: