Custom Machining Milling Grinding Steel Heavy Forged Forging Gear Wheel

Strength: production of various large, medium, small and special-shaped forgings. Application: cranes, military industry;

Basic Info

| Model NO. | 300mm |

| After-sales Service | Free After Service |

| Warranty | Free After Service |

| Condition | New |

| Certification | CE, RoHS, GS, ISO9001 |

| Standard | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized | Customized |

| Material | Iron |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Name | Forged Steel Wheels and Other Parts |

| Finish | Polish.Sandblast, Color Anodize, Plated and etc |

| Dimensions | Customer Required |

| Inspection | 100% |

| Process | Forging+Machining+Heating Treatment |

| Heat Treatment | Quenchining, Tempering, Annealing, Normalizing |

| Transport Package | Wooden Export Package |

| Specification | 900mm |

| Trademark | Leomon |

| Origin | China |

| HS Code | 86080090 |

| Production Capacity | 5000ton/Year |

Product Description

Strength: production of various large, medium, small and special-shaped forgings.Application: cranes, military industry, steel mills, hydraulics, mining, coking, bridge cranes, quay cranes, port machinery, locomotives, metallurgy, trains, stackers and reclaimers, ship unloaders, excavators, coke blockers, coke quenchers , Construction machinery and other domestic and foreign enterprises.

OEM steel forged metal agriculture forging parts, forging products series such as:

various wheels, pulleys, sprockets, gears, rings, gear rings, bushings, modules, cylinders, shafts, ring parts, piston rods, support seats, special-shaped parts, running wheels, crown wheels, ladle wheels, Slag tank wheels, mine wheels, wheel tyres, etc.

All products can be customized according to the customer's drawing size, material and chemical composition, free forging, die forging, heat treatment, finishing, and finishing at the same time as the finished product. The plasticity is controllable, the price is more favorable, and the quality is more reliable.

Have exported to South Korea, Japan, Russia, Brazil, Africa, Germany, Australia, Europe and many other countries.

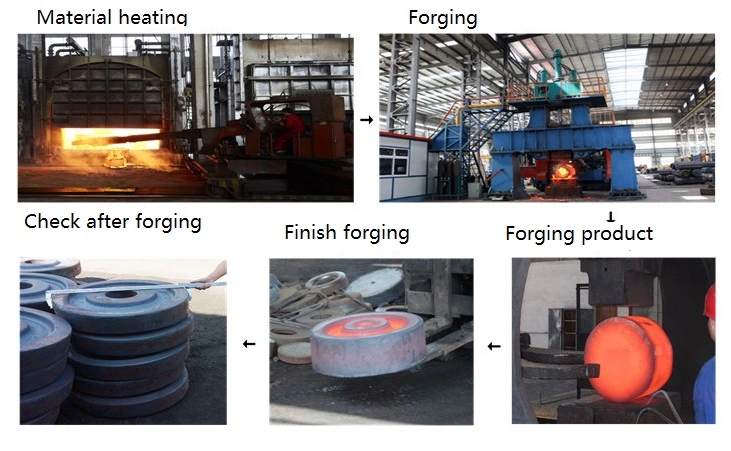

Production progress:

Raw materials preparing

Main Testing and Inspection Device

| No. | Device | Type | Qty | Status | Note |

| 1 | End quenching machine | DZJ-I | 1 | working | Testing |

| 2 | Electric resistance furnace | SX2-8-12 | 2 | working | Testing |

| 3 | Inverted metallurgic microscope | 4XCE | 1 | working | Inspection |

| 4 | High temperature box resistance furnace | SX2-4-13 | 1 | working | Testing |

| 5 | Automatic digital display Rockwell hard-tester | 200HRS-180 | 1 | working | Inspection |

| 6 | Electronic Brinell hardness tester | THB-3000 | 1 | working | Inspection |

| 7 | HR-150B Rockwell hardness tester | HR-150B | 1 | working | Inspection |

| 8 | Rapid multi-element analyzer | JS-DN328 | 1 | working | Inspection |

| 9 | Electric arc furnace | JSDL-8 | 1 | working | Testing |

| 10 | Rapid multi-element analyzer(C & S) | JS-DN328 | 1 | working | Inspection |

| 11 | Infrared thermometer | AR872 | 2 | working | Inspection |

| 12 | Portable chemical composition analyzer | AR872 | 2 | working | Inspection |

| 13 | Test specimen sampler | KW30-6 | 1 | working | Inspection |

You may also like

Send inquiry

Send now