Eco Friendly and Most Economical Tile Adhesive User Friendly Product for Fixing. Vitrified Tiles, Ceramic Tiles, Marble, Granite, Glass Mosaic

eco friendly and most economical tile adhesive user friendly product for Fixing. Vitrified Tiles, Ceramic Tiles, Marble,;

Basic Info

| Main Agent Composition | Unsaturated Polyester Resin |

| Characteristic | Adhesive |

| Promoter Composition | Curing Agent |

| Composition | Organic Material |

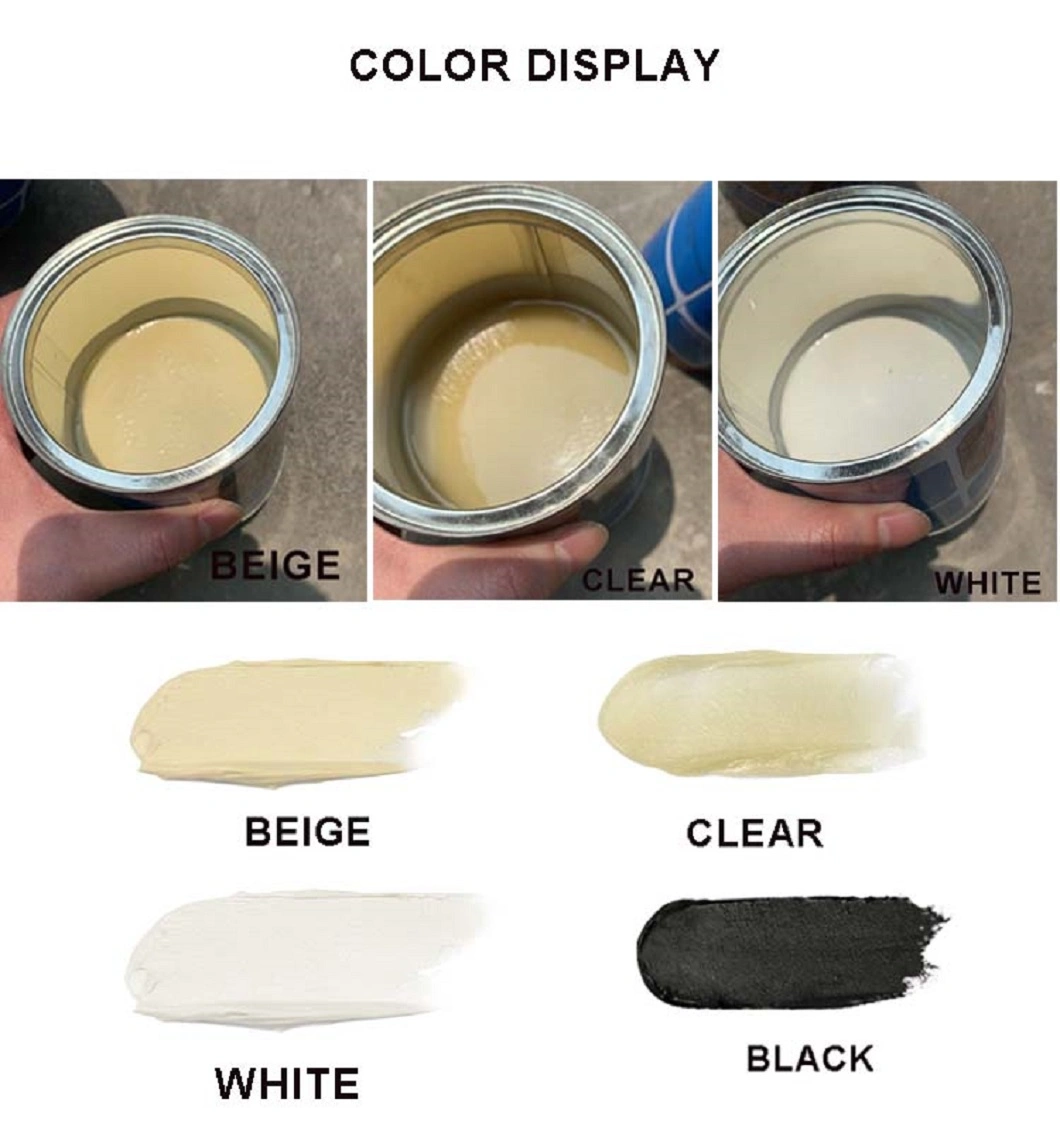

| Color | White |

| OEM | Available |

| Shelf Life | 9 Months |

| Loading Port | Wuhan |

| Package | Carton Box |

| Transport Package | Carton Box |

| Specification | 18L/bucket, 4L/bucket (4buckets/ctn) 3L/bucket (6 |

| Trademark | GNS |

| Origin | China |

| HS Code | 35061000 |

| Production Capacity | 20000bucket/Day |

Product Description

eco friendly and most economical tile adhesive user friendly product for Fixing. Vitrified Tiles, Ceramic Tiles, Marble, Granite, Glass Mosaiceco friendly and most economical tile adhesive user friendly product for Fixing. Vitrified Tiles, Ceramic Tiles, Marble, Granite, Glass Mosaic is manufactured with high pureness, stable and high quality materials, and under meticulous and cautious management and control, which have high quality. It is used for binding and repairing of all kinds stone materials and mending of seams and dents of the surface of the stone products. It possesses the character of high intensity, fast curing, weatherproof, corrosion resistance and can be polished.PRODUCT FEATURES

- Cure in short time

- Can be operated in cold weather (-10ºC~45ºC)

- High intensity, hard enough for polish

- No color change, cracking or shrinkage

- Weatherproof

- corrosion resistance

- High toughness after cured

APPLICATIONS AREAS

- Bonding and repairing of all kind of stones like marble, ceramics, and granite, so on.

- Fast fixing and pattern making

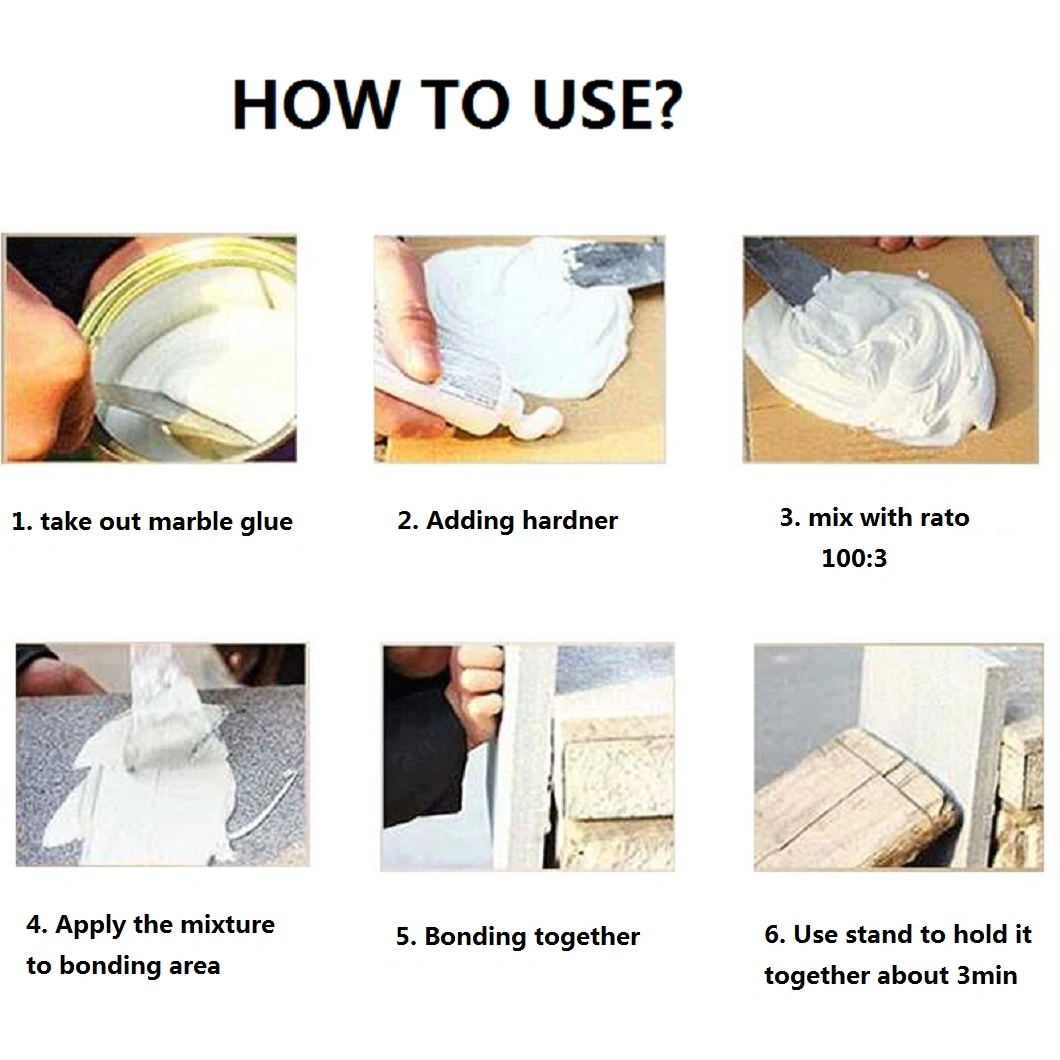

APPLICATION INSTRUCTIONS

- The surfaces must be clean and free from dust and grease

- Mix 100 parts of adhesive with 3 parts of hardener until a homogeneous mixture is obtained.

- Apply the mixture to the bonding area and hold it together about 3-5 minutes.

- Keep the assembled parts from moving during cure.

- Irritating to eyes and skin

- If eyes contact occurs, immediately flush eyes with plenty of water and consult doctor

- Use only in well-ventilated areas

- Mixing the components in correct ratio is critical since the amount of hardener affect working time

- Avoid contact with eyes. Keep non-cured adhesive away from children

| Mix ratio | 100 part adhesive with 3 part hardener | |

| Working time | 3-10 min | |

| Mixing Ratio | 3% | |

| Bending modulus of elasticity | ≥2500MPa | |

| Bending strength against Viscosity | ≥17.0MPa | |

| Impact Strength | ≥2.5MPa | |

| Press shear strength (stone-stone) | Stone-stone standard | ≥9 MPa |

| Heating process | ≥9 MPa | |

| Hot Water soak process | ≥6 MPa | |

| Alkali treatment | ≥6 MPa | |

| Freezing and heating cycle treatment | ≥6 MPa | |

| Press shear strength (stone-stainless steel) | Stone-stainless steel standard | ≥9 MPa |

You may also like

Send inquiry

Send now