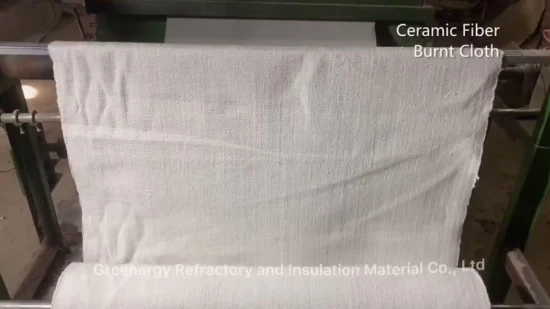

Greenergy Ceramic Fiber Insulation Burnt Cloth Ceramic Product

Basic Info

| Model NO. | Ceramic Fiber Burnt Cloth |

| Usage | High Temperature Insulating Material |

| Temprature Classification | 1260℃ |

| Chemical Composition: | Al2O3.SiO2, Al2O3 |

| Shape | Ceramic Fiber Textile |

| Manufacturing Technique | Spray Silk Rug |

| Kind | Ordinary Ceramic Fiber |

| Density | 463.9kg/M3 |

| Thickness | 2mm |

| Standard | Reach GB8624A(Ai) |

| Transport Package | Plastic Bag Inside, Carton Box Outside or with PAL |

| Specification | FG: Fiberglass; SS: Stainless steel; |

| Trademark | GREEWOOL |

| Origin | Hebei |

| HS Code | 6806101000 |

| Production Capacity | 8000t |

Product Description

Ceramic Fiber Burnt Cloth

Supply specifications| Inspection Report | ||||

| Density | 463.9kg/m3 | |||

| Thickness | 2mm | |||

| Combustion performance A(AI) | Incombustibility test | △T≤30ºC | 3ºC | Reach GB8624 A(AI)

|

| △m≤50% | 3% | |||

| t=0s(No continuous combustion) | 0s | |||

| Burn calorific value test | PCS≤2.0MJ/kg | 0.9MJ/k | ||

Ceramic fiber burnt cloth specification is a high performance industrial cloth made from ceramic fiber yarn, reinforced by high temperature alloy wire.

Ceramic fiber burnt cloth specification contains about 15% of organic fiber, ceramic fiber cloth ,when temperature are up, it will gradually be turned black carbide products of organic fiber, and has the phenomenon of smoking, the flame in some place, this is a normal phenomenon, as temperatures have been rising, it will not affect to use products .Sometime it gradually turned white, organic fibers which have been carbonizing on high temperature resistant inorganic materials such as ceramic fiber.

It can be used in all kinds of thermal equipment and heat conduction system for fire insulation and friction materials

High temperature resistance, low thermal conductivity, low thermal shock resistance ,low heat capacity

Excellent high temperature insulation, long service life

It has the ability to resist corrosion of non-ferrous metals such as aluminum and zinc

Temperature can reach 1000ºC under continuous use, temperature can reach 1260ºC under short time use

Good corrosion resistance again acid and alkali corrosion, corrosion resistance tagain molten metal such as aluminum and zinc

Good high temperature strength, thermal insulation performance

Greenergy Refractory &Insulation Material

Your reliable partner for refractory materials.

As one of the leading company of refractory products in China, Greenergy Refractory& Insulation Material enjoys close proximity to her customers, during long time in the market, we accumulate a lot of experiences in refractory materials for Steel plant, Boiler, Cement, Ceramics, Aluminum, Petrochemical and Metallurgy industries as well as other thermal treatment industries. We have a professional team for R&D, QOC, marketing and post services to our customers which in return help us gain plentiful of credit and reputation from the market.

We are committed to providing one-stop customized solution services from how-to-choose to final construction with varieties of refractory and insulation materials ranging from 500 ºC to 2000 ºC, including refractory ceramic fiber, bio soluble fiber, poly-crystalline fiber, insulating firebrick, refractory fire brick, monolithics and castables, microporous board, aerogel, calcium silicate boards and shapes, etc..

Our products have been highly praised by our customers from USA, UK, Italy, Germany, Turkey, India, UAE, Brazil, etc. We are striving to provide customers with comprehensive, one-stop and most suitable "energy saving" solutions to build a green-energy system.