Metal Mill Grinding Media Ceramic Fused Alumina Brown Aluminium Oxide Abrasive Material

Basic Info

| Model NO. | F24-F220/ 24#-220# |

| Other Name | Brown Aluminum Oxide |

| Certificate | ISO9001 |

| Color | Brown |

| Advantages | Factory |

| Grain Size | F8-F1200, P12-P2500, 0-1mm, 1-3mm,3-5mm,5-8mm, etc |

| Transport Package | Ton Bag with 25kg Small Bags |

| Specification | F8-F1200, P12-P2500, 0-1mm, 1-3mm,3-5mm,5-8mm, etc |

| Trademark | WANYU |

| Origin | China |

| HS Code | 2818101000 |

| Production Capacity | 35000tons/Year |

Product Description

Brown Fused Alumina is fused and crystallized under high temperature from a mixture of bauxite and other and other raw materials. It is characterized by its high hardness,good toughness and shape in size. Abrasives tools made of it are suitable for grinding metals of high-tensile strength such as: carbon steel,general-purpose alloy steel,annealed malleable iron and hard broze,etc.It also can be used as refractory materials.

Product Parameters

Brown Fused Alumina /Brown Aluminum Oxide for refractory

| Purpose | Specification | Chemical composition(%) | ||||

| Al2O3 | Fe2O3 | SiO2 | TiO2 | |||

| For refractory | Size sand | 0-1mm 1-3mm 3-5mm 5-8mm 8-12mm | 95 Min | 0.3 Max | 1.0 Max | 3.0 Max |

0-3mm 0-5mm 0-10mm 0-25mm | 95Min | 0.3 Max | 1.0Max | 3.0Max | ||

| Fine powder | 180#-0 240#-0 320#-0 | 94.5 Min | 0.3 Max | 1.5 Max | 3.5 Max | |

| Brown Fused Alumina /Brown Aluminum Oxide Physical Properties | |||||

| Color | True Density | Mohs Hardness | Melting Temperature | Crystal System | Refractory Temperature |

| Brown | 3.90g/cm3 | 9.0 | 2050°C | trigonal system | 1900°C |

Brown Fused Alumina for AbrasiveSandblastingPrecision casting

| Purpose | Specification | Chemical composition% | ||||

| Al2O3 | Fe2O3 | SiO2 | TiO2 | |||

| BFA For Abrasive | F | 4#-80# | ≥95.0 | ≤0.25 | ≤1.0 | ≤3.0 |

| 90#-150# | ≥95.0 | |||||

| 180#-240# | ≥94.5 | ≤0.3 | ≤1.5 | ≤3.5 | ||

| P | 8#-80# | ≥95.0 | ≤0.25 | ≤1.0 | ≤3.0 | |

| 100#-150# | ≥95.0 | |||||

| 180#-220# | ≥94.5 | ≤0.3 | ≤1.5 | ≤3.5 | ||

| W | 1#-63# | ≥94.0 | ≤0.5 | ≤1.8 | ≤4.0 | |

Packaging & Shipping

1 MT big bag or 25kg paper bag *40 bags on one pallet ;

As per customer's requirement

Company Profile

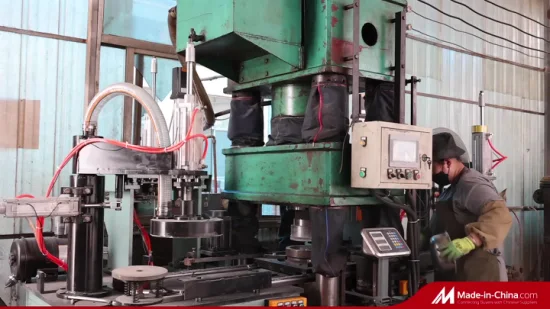

Our company enjoys a well-developed management system and quality system. We have various equipment including 7 smelting furnace, 4 grinding miller, 5 ball grinder, a central laboratory, an OMEC particle size analyzer, a Slap sieving machine, a microscope and other high-tech instruments. The annual production capacity can reach to 50,000 tons according to user demand sub-brand production. Our products, with high cleanliness, strong adaptability and stable performance, are exported to Europe, North and South America, Australia, Japan, Korea, Taiwan, Thailand, Singapore, Malaysia and other more than 30 regions and countries, enjoying a good reputation.

Our Advantages

1. We are a manufacturer, which can control the cost easier than trade companies also can give you an answer more quickly.

2. As a manufacturer, we know much in technique and can give you more support in technique problems.

3. Professional and experienced service team, specialized in abrasive production, more than 10 years.

4. Our products are complete in specifications of various sizes.

5. We enjoy a good reputation in the customers in domestic and overseas markets.

6. Large production capacity, short lead time of products.

7. 24*7 online service.

Certifications

FAQ

Q1: Are you a trading company of a factory?

A1: We are a professional factory, which has produced abrasive material since 2009.Q2: Can you provide free samples?A2: Yes, free samples under 1kg are provided.Q3: What is your payment term?A3: L/C or T/T 30% deposit, and 70% balance at sight of BL copy.Q4: What's your package?A4: 25kg/woven bag or a kraft paper bag. Package can be customized.